Executive Report: Future of the Global Gas Purging System Market — Key Drivers, Disruption Signals

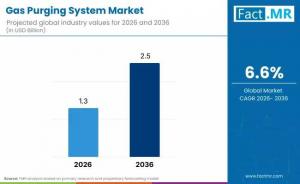

Global Gas Purging System Market Set for Robust Growth; Strategic Forecast Predicts Surge through 2036 Driven by Semiconductor and Energy Infrastructure

ROCKVILLE, MD, UNITED STATES, February 5, 2026 /EINPresswire.com/ -- As industrial sectors pivot toward ultra-high-purity (UHP) standards and decarbonization mandates, the global Gas Purging System Market is entering a decade of transformative expansion. According to the latest industry analysis, Gas Purging System Market Analysis - Size, Share, and Forecast Outlook 2026 to 2036, the market is poised to capitalize on a convergence of semiconductor manufacturing surges, the expansion of the hydrogen backbone, and stringent safety protocols in the oil and gas sector.Request for Sample Report | Customize Report |purchase Full Report - https://www.factmr.com/connectus/sample?flag=S&rep_id=14127

The Critical Role of Gas Purging in Modern Industry

Gas purging systems—the specialized equipment used to displace hazardous, reactive, or contaminating gases with inert substances like Nitrogen ($N_2$) or Argon ($Ar$)—have become indispensable for maintaining atmospheric integrity. This process is vital for:

Safety: Preventing explosions in volatile environments.

Integrity: Eliminating moisture and oxygen to prevent corrosion.

Purity: Ensuring zero-contaminant environments for 3nm and 2nm chip fabrication.

Market Dynamics: 2026–2036 Forecast Highlights

The forecast period 2026–2036 marks a shift from traditional manual purging to automated, IoT-integrated vacuum and pressure systems.

Feature Market Outlook (2026–2036)

Primary Growth Drivers Semiconductor fab expansions, LNG infrastructure, and Green Hydrogen logistics.

Leading Technology Vacuum Purging and Closed-loop Gas Recycling systems.

Regional Leader Asia-Pacific, led by semiconductor hubs in Taiwan, South Korea, and Malaysia.

Key Trend Integration of AI-driven flow control to reduce gas waste by up to 30%.

The Semiconductor Catalyst

The electronics industry remains the primary driver of high-purity purging demand. As fabrication plants (fabs) transition to sub-5nm nodes, the tolerance for atmospheric impurities has reached near-zero levels. Advanced purge chambers and inline gas monitoring systems are being integrated directly into lithography and etching equipment to support the production of AI-capable chips.

Energy Transition and the Hydrogen Back-Bone

The 2026 outlook highlights a significant uptick in demand from the renewable energy sector. With the commissioning of major hydrogen pipelines, such as the Hynetwork in Rotterdam, specialized purging systems are required to manage the unique leakage and embrittlement risks associated with hydrogen transport.

Technological Evolution: Beyond Traditional Methods

The industry is moving away from displacement or sweeping purges in favor of more efficient technologies:

Vacuum Purging: Emerging as a gold standard for pipeline commissioning, field tests in late 2025 demonstrated that portable vacuum units can reduce methane emissions by over 90% compared to traditional venting.

Intelligent Monitoring: Modern systems now feature real-time oxygen sensors and spectroscopic analysis to ensure the purging cycle is completed with mathematical precision, minimizing the use of expensive noble gases.

Challenges and Industry Headwinds

Despite the optimistic growth, the market faces hurdles. High capital expenditure (CAPEX) for automated UHP systems remains a barrier for small-scale industrial operators. Additionally, the complexity of maintaining global supply chains for specialty gases has led many providers to invest in on-site nitrogen generation and recovery systems to ensure operational continuity.

The next decade isn't just about moving gas; it's about the precision of the environment, says a leading industry analyst. From the cleanrooms of Silicon Valley to the LNG terminals of the Gulf Coast, the gas purging system is the silent guardian of both safety and product yield.

Strategic Outlook for Investors and Analysts

As we look toward 2036, the market is expected to see significant consolidation. Strategic mergers between industrial gas providers and IoT sensor manufacturers are likely, as Purging-as-a-Service models gain traction. This shift allows facilities to outsource atmospheric management, ensuring compliance with evolving EPA and EMA safety standards without the burden of equipment ownership.

About the Report

The Gas Purging System Market Analysis - Size, Share, and Forecast Outlook 2026 to 2036 provides a comprehensive look at the competitive landscape, regional growth pockets, and technological roadmaps for the next ten years. It serves as a definitive guide for stakeholders navigating the complexities of industrial gas management.

Related Reports

Gas Turbine Market https://www.factmr.com/report/gas-turbine-market

Gaskets and Seals Market https://www.factmr.com/report/gaskets-and-seals-market

Gas Liquefaction Chillers Market https://www.factmr.com/report/gas-liquefaction-chillers-market

Gas Insulated Transformer Market https://www.factmr.com/report/gas-insulated-transformer-market

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

"

S. N. Jha

Fact.MR

+1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.